Top Mining Containers: How to Choose the Best for Your Operations

In the rapidly evolving landscape of cryptocurrency mining, the choice of mining containers plays a pivotal role in the efficiency and success of mining operations. As demand for cryptocurrencies continues to soar, so does the necessity for optimized solutions that can house and protect mining equipment. Mining containers emerge as a viable option, providing a controlled environment that can enhance performance while ensuring security and sustainability.

Selecting the best mining containers for your operations involves understanding the various features and factors that contribute to effective mining. From insulation and ventilation to power supply management and ease of transport, each element plays a crucial role in safeguarding your investment and maximizing output. This guide aims to navigate the critical aspects of mining containers, allowing operators to make informed decisions tailored to their specific needs and operational goals. In this competitive arena, a well-chosen mining container can significantly impact profitability and operational resilience.

Understanding Mining Containers and Their Purpose

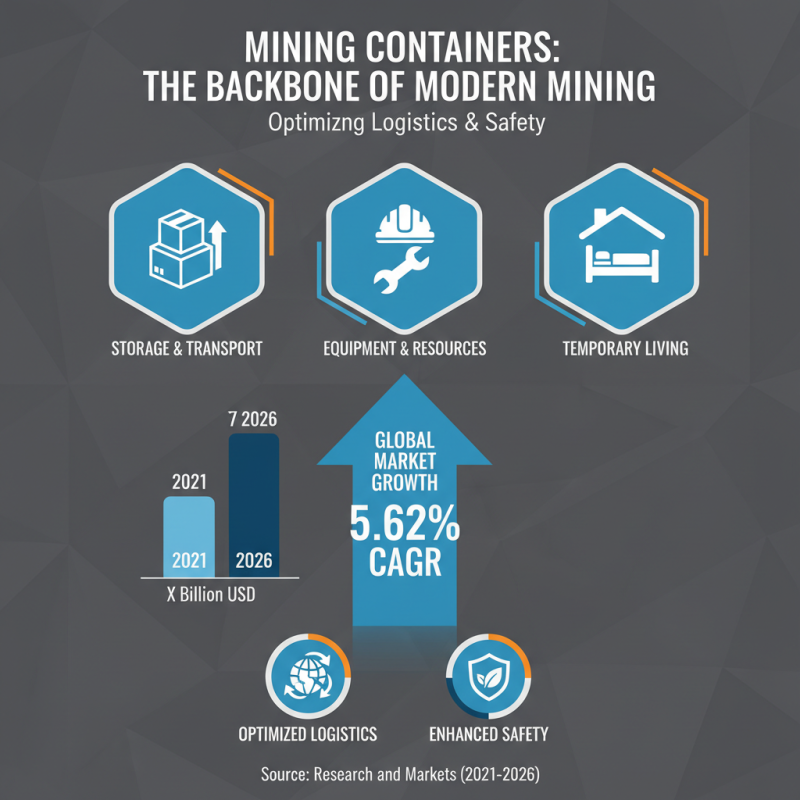

Mining containers play a crucial role in the mining industry, serving as essential units for storage, transportation, and even temporary living quarters. Their primary purpose is to provide a secure and efficient way to manage resources and equipment. According to a report by Research and Markets, the global mining containers market is expected to grow at a compound annual growth rate (CAGR) of 5.62% from 2021 to 2026. This growth underscores the increasing necessity for optimized logistics and enhanced safety compliance in mining operations.

The design and functionality of mining containers have evolved significantly, with a focus on durability and versatility. Many modern containers are equipped for specific needs, such as hazardous materials storage or providing mobile office spaces in remote areas. For instance, a study from the International Council on Mining and Metals indicates that approximately 30% of operational delays in mining are due to poor logistics planning. By leveraging specialized containers, companies can improve their operational efficiency, minimize downtime, and ensure that necessary resources are readily available where they are most needed. As mining operations become more complex, the importance of choosing the right containers tailored for specific functions cannot be overstated.

Key Factors to Consider When Selecting Mining Containers

When selecting mining containers for your operations, there are several key factors to consider to ensure you choose the best option for your needs. One critical aspect is the container's size and capacity. Depending on the scale of your operations, you must assess how much material you will be storing or transporting. It’s also essential to evaluate the material of the container; options can range from steel to aluminum, impacting durability, weight, and resistance to harsh environmental conditions.

Tips: Always consider the expected lifespan of the container, along with potential wear and tear from transportation or environmental factors. Investing in robust materials can lead to long-term savings by reducing replacement frequency.

Another important factor is the container's design and accessibility. Containers come in various configurations, and selecting one that allows for easy loading, unloading, and maintenance can significantly enhance operational efficiency. Make sure to review features like ventilation, security options, and insulation, especially if you are dealing with sensitive materials that require controlled environments.

Tips: Before making a purchase, create a checklist of essential features that meet your operational requirements. This will help you make informed decisions and ensure that your selected containers align with your operational goals.

Types of Mining Containers and Their Applications

When selecting the best mining containers for your operations, it's essential to understand the various types available and their specific applications. Mining containers generally fall into two categories: storage containers and transport containers. Storage containers are designed for safe, secure storage of tools, equipment, and supplies on-site. They often feature robust materials and secure locking mechanisms to withstand harsh environments. On the other hand, transport containers are specifically for moving resources from one location to another, featuring durability and lightweight designs to facilitate easy handling.

**Tips for Choosing the Right Container:** Consider the specific needs of your mining site. If the location experiences extreme weather conditions, investing in containers with enhanced insulation and weatherproofing can ensure your materials remain protected. Additionally, assess the weight and type of goods you'll be storing or transporting. For example, when dealing with heavy machinery parts, opt for containers that can support significant weight without compromising safety.

Another critical factor to consider is mobility. If your operations frequently relocate, look for containers equipped with wheels or fork slots for easy transport. This can save valuable time and reduce manual labor. Additionally, ensure that the containers you choose comply with safety regulations and standards to minimize risk during operations.

Evaluating the Durability and Security Features of Containers

When selecting mining containers for operations, durability and security are paramount. According to a report by the International Council on Mining and Metals (ICMM), the longevity of containers used in mining typically ranges between 10 to 15 years, but this can vary widely based on the materials used and environmental conditions. Containers made with high-grade steel and advanced corrosion-resistant coatings can significantly extend their lifespan, thereby reducing operational costs related to frequent replacements. This durability is essential in mining operations, where containers are often exposed to harsh weather, abrasive materials, and potential physical damage from equipment.

Security is another critical consideration in the evaluation of mining containers. Data from the Global Mining Security Report indicates that theft and vandalism account for approximately 25% of losses in the mining industry. Therefore, containers that are equipped with anti-tamper locks, reinforced structures, and alarm systems can help mitigate these risks significantly. Furthermore, implementing proper inventory management and tracking technologies within these containers can enhance security measures. Effective container designs not only provide robust security features but also contribute to the overall operational efficiency and safety of mining projects.

Top Mining Containers: How to Choose the Best for Your Operations

| Container Type | Durability Rating | Security Features | Size (ft) | Weight Capacity (lbs) | Cost ($) |

|---|---|---|---|---|---|

| Standard Shipping Container | High | Lockable doors, Heavy-duty steel | 20 | 48,000 | 2,500 |

| Reinforced Storage Container | Very High | Integrated alarm, Security locks | 40 | 60,000 | 4,000 |

| Mine-Specific Container | High | Panic button, Enhanced locks | 30 | 50,000 | 3,500 |

| Custom Security Container | Ultra High | Digital lock, Surveillance camera | 20 | 40,000 | 5,500 |

Cost-Effectiveness and Return on Investment in Mining Containers

When selecting the best mining containers for your operations, the emphasis on cost-effectiveness and return on investment (ROI) cannot be overstated. Recent industry reports indicate that the total cost of ownership for mining containers can be significantly reduced by choosing models that optimize both functionality and durability. For instance, investing in high-quality, weather-resistant materials can lead to lower maintenance costs and extended lifespan, ultimately enhancing ROI over the long term.

Moreover, operational efficiency is key when calculating the returns on investment. Data from market analyses show that efficient container solutions can streamline supply chain operations by up to 30%, thereby reducing delays and operational costs. By implementing modular, stackable containers, mining operations can not only save on transportation costs but also increase their on-site storage capacity without a proportional increase in footprint. This efficient use of space bolsters productivity and contributes to a more favorable cost-benefit ratio.

Additionally, the arrangement of resources and equipment within these containers plays a critical role in optimizing workflow. A study revealed that projects that strategically design container layouts experience a productivity boost of approximately 15%, emphasizing the importance of thoughtful design in maximizing the ROI. By carefully evaluating not just the purchase price but also the functional advantages of mining containers, operators can significantly enhance their financial performance and operational success.

Top Mining Containers: Cost-Effectiveness and ROI Analysis

Related Posts

-

The Ultimate Guide to Sourcing the Best Miner Power Suppliers for Your Business

-

Unmatched Quality of Best Mining Containers From China Meeting Global Industry Standards

-

Exploring Innovative Alternatives for Bitcoin Mining Shipping Container Solutions

-

What Makes Container Mining a Game Changer in the Industry

-

How to Optimize Your Container Mining Strategy for Maximum Efficiency

-

How to Optimize Your Bitcoin Mining Container for Maximum Efficiency